What Causes Paint To Turn Powdery On Inside Of House

NCR-134

WOOD FINISHING

Purdue Academy

Cooperative Extension Service

West Lafayette, IN 47907

Discoloration of Business firm Paint--Causes and Cures

Daniel L Cassens, Department of Forestry and Natural Resources. Purdue Academy

William C. Feist, Forest Products Laboratory. Forest Service. U.S. Section of Agriculture

Nether normal conditions paint deteriorates by start soiling or past a slight accumulation of clay. Adjacent, a flattening stage develops when the coating gradually starts to chalk and erode away. Unfortunately, paint is sometimes discolored by mildew, blue stain, wood extractives and metals long before repainting is necessary. In these cases, a simple repainting will not correct the problem for long. Furthermore, excessive painting is expensive, and a build-up of paint on the wood surface may atomic number 82 to cross-grain keen or other severe paint failures. If the onetime pigment surface is not properly cleaned before repainting, intercoat peeling may also result.

MILDEW

Mildew is probably the well-nigh common crusade of house paint discoloration (Figure 1). Mildew is a class of stain fungi or microscopic plant life. The most common species are black, but some are red, light-green, or other colors. It grows most extensively in warm humid climates simply is too found in cold northern states. Mildew may be found anywhere on a building, but it is most common on walls behind copse or shrubs where air movement is restricted. Mildew may also be associated with the dew pattern of the house. Dew volition form on those parts of the house which are not heated and volition cool rapidly such as eaves and the ceilings of carports and porches. This dew and then provides a source of moisture for the mildew.

Effigy 1. Mildew is well-nigh common in shaded or protected areas.

Mildew fungi can be distinguished from dirt past examination under a high-power magnifying glass. In the growing stage, when the paint surface is damp or wet, the mucus is characterized by its threadlike growth. In its dormant stage, when the surface is dry out, it has numerous egg-shaped spores; by contrast, granular particles of dirt are irregular in size and shape. A elementary exam for the presence of mildew on paint can be made by applying a drib or ii of household bleach solution (5 percentage sodium hypochlorite) to the stain. Mildew will usually bleach out in one or two minutes. Stain that does not bleach is probably dirt. Information technology is important to use fresh bleach solution. Bleach deteriorates upon standing and loses its potency.

How Paint Makeup Affects Mildew

Some paints are more vulnerable than others to attack by mildew fungi. Zinc oxide, a mutual paint pigment in meridian coats, inhibits the growth of mildew. Titanium dioxide, another common paint pigment, has very fiddling inhibiting effect on mildew.

Considering oil-base of operations paints, mildew progresses more readily on exterior flat house paint than on exterior enamel. Paints containing linseed oil are very susceptible to mildew. Of the bachelor h2o-base of operations paints, acrylic latex is the most mildew resistant. Porous latex (h2o-base) paints without a mildewcide applied over a primer glaze with linseed oil volition develop astringent mildew in warm, damp climates.

Mildewcides are poisons for mildew fungi. The pigment characterization should indicate if a mildewcide is present in the paint. If it is non present, it can sometimes be added past the local pigment dealer. Paint containing mildewcides, when properly applied to a clean surface, should prevent mildew problems for some fourth dimension.

Prevention and Cure

New Wood Surfaces

In warm, damp climates where mildew occurs frequently, use a paint containing zinc oxide and a mildewcide for meridian coats over a primer coat which also contains a mildewcide. For mild cases of mildew, use a paint containing a mildewcide.

Painted Wood Surfaces

Before repainting, the mildew must be killed, or information technology will abound through the new pigment coat. To kill mildew and to make clean an area for general appearance or for repainting, utilize a bristle castor or sponge to scrub the painted surface with the following solution:

1/iii cup household detergent one quart (5 percent) sodium hypochlorite (household bleach) iii quarts warm water *Encounter warning later in this file.

When the surface is clean, rinse it thoroughly with fresh h2o from a hose. Avoid splashing the solution on yourself or on shrubbery or grass as it may have harmful effects. Before the cleaned surface tin can become contaminated, repaint it with a paint containing a mildewcide.

Water-SOLUBLE EXTRACTIVES

In cantankerous section, many trees incorporate a dark primal core chosen heartwood and a light colored outer band called sapwood. Dark colored heartwood contains water-soluble extractives, while sapwood does non. These extractives tin occur in both hardwoods and softwoods. Western red cedar and redwood are two mutual softwood species used in construction. They both incorporate big quantities of extractives. The extractives give these species their attractive color, good stability and natural disuse resistance, simply they can likewise discolor paint. Forest such equally Douglas-fir can too have occasional extractive staining bug.

When extractives discolor pigment, moisture is usually the culprit. The extractives are dissolved and leached from the wood past water. The water then moves to the paint surface, evaporates and leaves the extractives behind every bit a reddish-brown stain.

Diffused discoloration from woods extractives is caused by h2o which comes from rain and dew that penetrates a porous or sparse paint glaze. It may also be caused past pelting and dew that penetrate joints in the siding or by water from faulty roof drainage and gutters.

Diffused discoloration is best prevented by post-obit proficient painting practices. Utilise a water-repellent preservative or water repellent to the bare wood before priming. Utilise an oil-based, stain-resistant primer or a latex primer particularly formulated for use over staining forest. Do not use porous paints such equally apartment alkyds and latex directly over the staining-type wood. If the wood is already painted, clean the surface, apply an oil-based or latex stain-resistant primer and then top coat. Earlier priming and repainting, apply a water-repellent preservative or water repellent to any forest left bare from peeling paint.

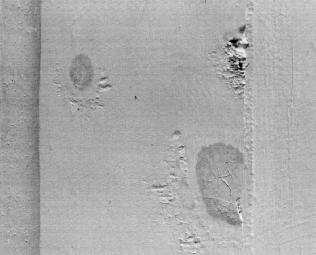

A run down or streaked type of discoloration tin can also occur when h2o-soluble extractives are present (Figure 2). This discoloration results when the dorsum of the siding is wetted, the extractives are dissolved, and and then the water runs down the face of the painted boards from the lap joint.

Figure ii. A streaked type of water soluble extractive discoloration tin result from water wetting the back of one piece of siding and then running down on the front of the next piece.

Water which produces a run downwardly discoloration can result from water vapor inside the house moving to the exterior walls and condensing during common cold weather. Major sources of h2o vapor are humidifiers, unvented apparel dryers, showers, normal respiration, and wet from cooking and dish-washing. Run down discoloration may as well be caused by water draining into outside walls from roof leaks, faulty gutters, ice dams, and wind driven rain and snow at louvers.

Run downwardly discoloration tin can be prevented by reducing condensation or the accumulation of moisture in the wall. New houses or those under-going remodeling should accept a vapor barrier (continuous half-dozen mil polyethylene sheet) on the inside of all exterior walls. If a vapor barrier is not practical, the inside of all exterior walls should be painted with a vapor resistant pigment. H2o vapor in the firm tin be reduced by using exhaust fans vented to the outside in bathrooms and kitchens. Dress dryers should be vented to the outside and not to the crawl infinite or cranium. Avoid the utilise of humidifiers. If the house contains a clamber space, the soil should be covered with a vapor barrier to forbid migration of water into the living quarters.

Water from pelting and snow can be prevented from entering the walls by proper maintenance of gutters and the roof. Ice dam germination tin can exist prevented by installing adequate insulation in the cranium and by providing proper ventilation. For gable roofs, vents should be provided at the gable ends and should be about 1/300 of the ceiling area. More than positive air movement can be obtained if additional openings are provided in the overhang. Hip roofs should have air inlet openings in the louvers and several smaller roof vents located near the edge.

Removing Discoloration

If discoloration is to exist stopped, moisture issues must exist eliminated. Run downwards discoloration volition usually weather away in a few months. Even so, discoloration in protected areas tin can go darker and more difficult to remove with time. In these cases, wash the discolored areas with a mild detergent before long after the problem develops. Pigment cleaners are effective on darker stains.

BLUE STAIN

Bluish stain is caused by microscopic fungi that ordinarily infect the sapwood of all woody species. Although microscopic, they produce a blueish-black discoloration of the wood. Blue stain does non weaken wood structurally, but conditions which favor stain development are also ideal for serious forest decay and pigment failure.

Wood in service may contain blue stain, and no detrimental effects will result so long as the moisture content is kept below 20 percent. Wood in properly designed and well maintained houses usually has a moisture content of 8-13 percent. However, if the wood is exposed to moisture such as rain, condensation or leaking plumbing, the moisture content volition increment, and the blue stain fungi volition develop.

To prevent bluish stain from discoloring paint, follow skillful construction and painting practices. Get-go, do whatever is possible to continue the wood dry. Provide an acceptable roof overhang, and properly maintain the shingles, gutters and downspouts. Window and door casings should slope out from the house, thus allowing h2o to drain away rapidly. Use a vapor bulwark on the interior side of all exterior walls to prevent condensation in the wall. Vent apparel dryers, showers and cooking areas to the outside, and avoid the apply of humidifiers. Untreated forest should be treated with a water-repellent preservative, and so a nonporous mildew-resistant primer and finally at least one top coat as well containing a mildewcide. If the wood has already been painted, remove the onetime paint and allow the woods to dry out thoroughly. Utilize a water-repellent preservative, and and so repaint as described above.

A 5 percent sodium hypochlorite solution (ordinary household bleach) may sometimes remove blue stain discoloration, simply it is non a permanent cure. Be sure to use fresh bleach since its effectiveness can diminish with age. The moisture problem must be corrected if a permanent cure is expected.

IRON STAIN

Rust may be 1 type of staining trouble associated with iron. When standard ferrous nails are used on exterior siding then painted, a cherry-red-dark-brown discoloration may occur through the pigment and immediate vicinity of the nail head. To prevent rust stains, utilize corrosion-resistant nails. These include high quality galvanized, stainless steel and aluminum nails. Poor-quality galvanized nails can corrode easily and, like ferrous nails, can crusade unsightly staining of the wood and paint. The galvanized heads on nails should not "scrap loose" every bit they are driven into the wood. If rust is a serious trouble on a painted surface, the nails should be countersunk, caulked, spot primed and and then top coated.

Unsightly rust stains may also occur when standard ferrous nails are used in association with whatsoever of the other finishing systems such as solid colour or opaque stains, semitransparent penetrating stains and water-repellent preservatives. Rust stains tin as well result from screens and other metal objects or fasteners which are discipline to corrosion and leaching (Figure 3).

Figure iii. Metal screens and fasteners tin corrode and later discolor paint as leaching occurs.

A chemical reaction with iron resulting in an unsightly blue-black discoloration of wood can also occur. In this example, the atomic number 26 reacts with sure wood extractives to form the discoloration. Ferrous nails are the most common source of iron for chemic staining (Figure iv), just problems accept as well been associated with traces of atomic number 26 left from cleaning the wood surface with steel wool or wire brushes. The discoloration tin sometimes become sealed beneath a new finishing system.

Figure 4. Blue-black discoloration resulting from the use of ferrous nails.

Oxalic acid will remove the blue-blackness chemical discoloration providing it is non already sealed beneath a finishing system. The stained surface should be given several applications of the solution containing at least one pound of oxalic acid per gallon of h2o, preferably hot. Later the stains disappear, the surface should be thoroughly washed with warm, fresh water to remove the oxalic acid and any traces of the chemic causing the stain. If all sources of iron are not removed or protected from corrosion, the staining problem may reoccur. Caution should exist exercised when using oxalic acid since this chemical is toxic.

CHALKING

Chalking results when a paint film gradually weathers or deteriorates, releasing the individual particles of pigment. These individual particles deed similar a fine powder on the paint surface. Most paints chalk to some extent. This phenomenon is desirable since it allows the paint surface to be self-cleaning. Notwithstanding, chalking is objectionable when it washes downwardly over a surface with a different colour (Effigy 5) or when it causes premature disappearance of the paint film through excess erosion.

Figure v. Some paints or stains chalk badly and can discolor a lower surface every bit they wash down over information technology.

Discoloration bug from chalking can be prevented by selection of a paint with the appropriate chalking tendencies. The manner in which a paint is formulated may determine how fast it chalks. Therefore, if chalking is likely to be a trouble, select a paint which the manufacturer has indicated will chalk slowly.

When repainting surfaces which have chalked excessively, proper preparation of the old surface is essential if the new pigment glaze is expected to concluding. Scrub the former surface thoroughly with a detergent solution to remove all old deposits and dirt. Rinse thoroughly with clean water before repainting. The use of a top quality oil-based primer may be necessary before latex acme coats are used. Otherwise, the new pigment coat volition skin. Discoloration or chalk which has run down on a lower surface may be removed by vigorous scrubbing with a adept detergent. This discoloration will also gradually weather away if the chalking problem on the painted surface has been corrected.

Brownish STAIN OVER KNOTS

The knots in many softwood species, specially pine, contain an affluence of resin. This resin can sometimes cause paint to peel or turn brown (Figure half dozen). In almost cases, this resin is "set" by the high temperatures used in kiln drying construction lumber.

Figure half-dozen. Brown discoloration of pigment from resin exudation from a knot.

Skillful painting practices should eliminate or command brown stain over knots. Apply a good primer to the blank forest first. And then follow with two summit coats. Do non apply ordinary shellac or varnish to the knot surface area first as this may result in early pigment failure.

ADDITIONAL INFORMATION

The following are available from the Forest Products Laboratory, One Gifford Pinchot Drive, Madison, WI 53705-2398:

- "Painting and Finishing," Affiliate 16 from Forest Handbook: Wood as an Technology Textile USDA Agricultural Handbook No. 72,1987,29 pp.

- "Wood Finishing: Weathering of Forest." USDA Forest Service Research Note FPL-0135, revised 1975, four pp.

The following are available from the state Extension Services listed at the end of this publication:

"Finishing Exterior Plywood, Hardboard, and Particleboard." NCRExtension Publication 132, revised 1988, half dozen pp.

"Paint Failure Problems and Their Cure." NCR Extension Publication133, revised 1988, 6 pp.

"Selection and Application of Outside Finishes for Wood." NCRExtension 135, revised 1988, viii pp.

"Finishing and Maintaining Wood Floors." NCR Extension Publication136, revised 1988, 8 pp.

The following is available from the Superintendent of Documents, U.S. Government Printing Function, 710 North Capitol Street, Washington, DC 20402 (guild past title and stock number):

"Finishing Woods Exteriors; Pick, Application, and Maintenance." USDA Agricultural Handbook No. 647, SN #0011-000-044-fifty-8,1986,56 pp. Price: $3.50 (subject to change without discover).

Slide/Tape Presentation

- "Exterior Finishes for Woods." Agency of Audio Visual Educational activity, Box 2093, Madison, WI 53701.

Acquittance is given to the Forest Products Laboratory. Forest Service. U.Due south. Department of Agriculture. Madison. Wisconsin, for financial assistance in sup port of the preparation of this publication.

WARNING

Exercise non mix bleach with ammonia or with any detergents or cleansers containing ammonia! Mixed together the two are a lethal combination, similar to mustard gas. In several instances people have died from animate the fumes from such a mixture. Many household cleaners comprise ammonia, so be extremely careful with what types of cleaners you mix bleach.

Use caution with wood finishes which contain pesticides. When used improperly they can be injurious to human being, animals and plants. For safe and constructive usage, follow the directions, and listen all precautions on the labels. It is appropriate to wear unlined protective gloves and to cover nearby found life when using any material containing pesticides.

Avoid spraying a pesticide wherever possible. Drift from a pesticide, applied equally a spray, may contaminate the surrounding surround.

Store finishes containing pesticides in original containers under lock and key out of reach of children and pets and away from foodstuffs. Follow recommended practices for the disposal of surplus finishing materials and containers.

Note: Registrations of pesticides are under constant review by the Environmental Protection Bureau and the Department of Agronomics. Use only pesticides that bear a Federal registration number and carry directions for home and garden use. Since the registration of pesticides is under abiding review past State and Federal authorities, you should consult with a responsible State bureau as to the current status of the pesticides discussed in this report.

Sponsored by the Cooperative Extension Services of Illinois, Indiana, Iowa, Kansas, Michigan, Minnesota, Missouri Nebraska, Northward Dakota, Ohio, South Dakota, Wisconsin, and Lincoln University-Missouri. Printed and distributed in cooperation with Extension Service, U.S. Department of Agriculture, Washington, D.C.

Programs and activities of the Cooperative Extension Service are bachelor to all potential clientele without regard to race, colour, sex, historic period, national origin, or handicap.

In cooperation with the North Central Region Educational Materials Project.

Rev 3/88

Issued in furtherance of Cooperative Extension work, Acts of Congress of May 8 and June 30, 1914, in cooperation with the U.S. Section of Agronomics and Cooperative Extension Services of Illinois, Iowa, Kansas, Michigan, Minnesota, Missouri Nebraska, North Dakota, Ohio, South Dakota, and Wisconsin. H.A. Wadsworth, Managing director, Purdue University Cooperative Extension Service, West Lafayette, IN 47907.

Source: https://www.extension.purdue.edu/extmedia/ncr/NCR-134.html

Posted by: hatfieldemenceapery.blogspot.com

0 Response to "What Causes Paint To Turn Powdery On Inside Of House"

Post a Comment